OEM Earrings Success Story

This case study details how Haosen partnered with a new client to bring their debut earrings collection to life, turning a vision into a tangible product.

Initial Contact & Design Proposal

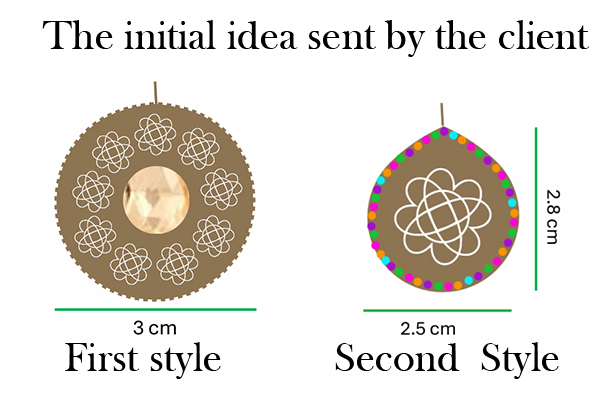

Our journey began when a new customer, who found us on Google, reached out. They were on the verge of launching their very first jewelry line—earrings, to be exact—and needed a manufacturing partner to help them get the ball rolling. They sent over design sketches and a list of specs: material, plating color, rhinestone color, logo effect, and hardware. Our team took a look and assured them their designs were a slam dunk—completely doable.

Quotation and Design Adjustments

During the quoting process, we identified opportunities to optimize costs without compromising design intent:

Rhinestone Colors: Multiple colors increased costs. After discussion, the client kept the original multi-color design for the first style and Changed the edge rhinestones to white in the second style

After alignment on adjustments, the final specifications were locked in:

From Design to Earrings Model

With all the specs confirmed and the sample fee paid, our production team got down to business. They took the client’s sketches and turned them into detailed 3D draw.

When our sales team reviewed the designs, they found a serious flaw: the six flowers on the first earring style were all facing different directions. We knew this would be a deal breaker. Our designer quickly went back to fix it. Once we double-checked everything, we sent the final version to the client.

The Manufacturing Process

Our production team followed our usual routine: prepping the metal blanks, polishing, plating, and meticulously setting each rhinestone.

As soon as the samples were finished, we shot a video to show the client the final product. They were absolutely over the moon, thrilled with both the design and our service. It was a true collaboration that turned their dream into a dazzling reality.