- Jasper Jiang

- No Comments

Being a Chinese professional manufacturing factory of stainless steel jewelry, Haosen Hardware & Jewelry Co., Ltd., takes a specific example of a 316L stainless steel custom-made gold bracelet as a sample procedure for converting flat fashion jewelry designs into beautiful fashion jewelry through casting jewelry manufacturing processes.

Initial Development and DFM (Design for Manufacturability) Audit

Before formal mold construction, my team will perform an engineering review of the exact dimensions within the design plans for:

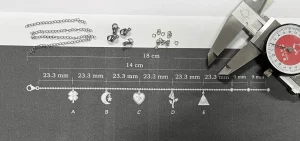

The order for the custom designs consists of a variety of personalized 316L stainless steel pendants, such as four-leaf clover, moon and star, rose, micro-set heart, and pyramid eye.

- Technical issues: The hardness of stainless steel is extremely high; how to #8000 mirror-polish it on the edge with a thickness of only 1.4mm? How does one attach 0.8mm cubic zirconia stones to 316L stainless steel?

- Three-dimensional data modeling: One-to-one modeling of difficult three-dimensional forms like PART D (rose).

- Shrinkage Compensation Calculation: Because of the approximate casting shrinkage rate of 316L of 4%-4.5%, the placement of the stone (0.8mm CZ in PART C (heart-shaped)) will be pre-sized to guarantee the precision of micro-setting.

Core Production Process of A Small Pendant

Due to the asymmetrical 3D structures of the pendant (e.g., the moon and rose), the best method to cast them would be the lost-wax casting process:

- Wax mold making and assembling: Wax molds of five components (A-E) are created using injection molding with a rubber mold.

- Making shell ceramic: The shell coat is made from ceramic slurry, capable of withstanding the melting point of 316L stainless steel above 1750°.

- Vacuum induction melting & casting: Casting of the steel is carried out in a vacuum to ensure that the stainless steel does not oxidize, thereby filling all the details of parts B & C.

- Shell removal and gate cutting: The cutting of the gates is done with a carbide saw blade, while cleaning of the castings takes place.

Precision Polishing & Surface Engineering

- Initial grinding and deburring: All pendant edges are rounded for a comfortable finishing touch.

- Multi-stage mirror polishing: The 1.4mm side is physically polished to a #8000 grit mirror finish.

- Laser internal engraving: High precision laser engraving is employed on PART E (pyramid eye) and PART C (micro-set heart).

Vacuum Ion Plating Process

We adopt the advanced PVD vacuum plating technology to give stainless steel a luxurious golden texture.

- Ultrasonic deep cleaning: Through 7 cleaning steps, wax and fingerprints are thoroughly removed, allowing for molecular-level adhesion of the coating.

- Plasma bombardment: the stainless steel surface in a vacuum furnace is activated, enhancing wear resistance to improve the coating.

- 18K PVD gold plating: the target material of 18K gold is used to strike an ion plate, with a thickness up to 0.05μm; according to Jasper’s standard, it needs to pass the artificial sweat test for 24 hours to guarantee that the gold color will not fade for 1-2 years in ordinary daily use.

Cubic Zircon Setting Process

- Manual Micro-Pave Setting: This is done with the aid of a microscope.

- PART B: Setting 1.5mm CZ round stones. We use only 5A grade CZ.

- PART C: Precisely setting 0.8mm CZ round stones along the heart-shaped edge.

- Stability Check: Making sure that every precious stone is set tightly enough to avoid being detached by everyday impacts.

Chain Manufacture and Integral Bracelet Assembly

- 316L Chain Cutting: Cut the chain accurately to the required overall length of 18cm as per the drawings (14cm chain part + extension chain).

- Laser Pulse Welding:

- Mount the five pendants (A-E) to the chain with an accurate spacing of 23.3mm.

- Weld the ends of the chain, lobster clasp, and the 9mm adjustment buckle.

- Jasper’s Standard: The utilization of instant high-temperature laser Technology to secure Molecular bonding, thereby producing the smallest spots possible and meeting tensile strength specifications.

- Laser marking with the customer’s proprietary brand name.

Final Processing and QC(Quality Control)

- Passivation Process: The whole bracelet implements a chemical passivation treatment in which a 50nm anti-oxidation coating is regenerated. This helps in maintaining the superior level of corrosion-resistance that 316L Stainless Steel possesses.

- Ultrasonic Cleaning: Removes residues of polishing paste and fingerprints.

- Quality Audit:

- Dimensional Verification: It ensures that the collective length is standard at 18 cm.

- Tensile testing: Verifies that welding locations are secure.

- Visual Check: It ensures that the gemstones are not loose, nor are they scratched.

- Color difference testing: The PVD Gold finish is color-matched with a standard illumination.

Conclusion

For a jewelry brand’s custom 316L stainless steel bracelets, while the design drawing is only a blueprint, the real difficulty lies in converting it into reality using technology like #8000 grit polishing, 18K gold PVD plating, and seamless laser welding.

Being a Chinese stainless steel jewelry manufacturing factory with so much industry knowledge, Haosen Jewelry provides more than just products — they also provide engineering reliability stemming from 16 years of experience.

Jasper’s Recommendation: “If you are seeking a business partner with the capability of accurately replicating your 1.4mm ultra-thin design specification and precision micro-inlays at the size of 0.8mm, I can bring our engineering team to give you the most professional DFM audit support,” I wrote in my response.

Turning design blueprints into reality

For assistance, contact our Jasper team directly. Our team will offer you the most professional DFM (Design For Manufacturing) audit and production services. We can help your brand stand out in the fashion jewelry area.

Get a Quote Now

Jasper Jiang

Haosen Jewelry Chief Technology Officer, 16 years of experience in multi-material research and development.