Vintage Rinstones Bracelets

| Price | USD2.87 |

|---|---|

| Raw Material | Brass |

| Stone | Crystal, Glass |

| Color | Antique bronze Plated |

| MOQ | 30 |

| Size | custom available |

Width:11mm

Length:18+5cm

Weight:18.6g

SKU:001S39

Browse More Products for Inspiration

Related products

-

Stainless Steel Bracelets

OEM ODM Stainless Steel Daisy Flower Chain Bracelet for Women

$1.00 Add to cartRated 0 out of 5

Custom Options

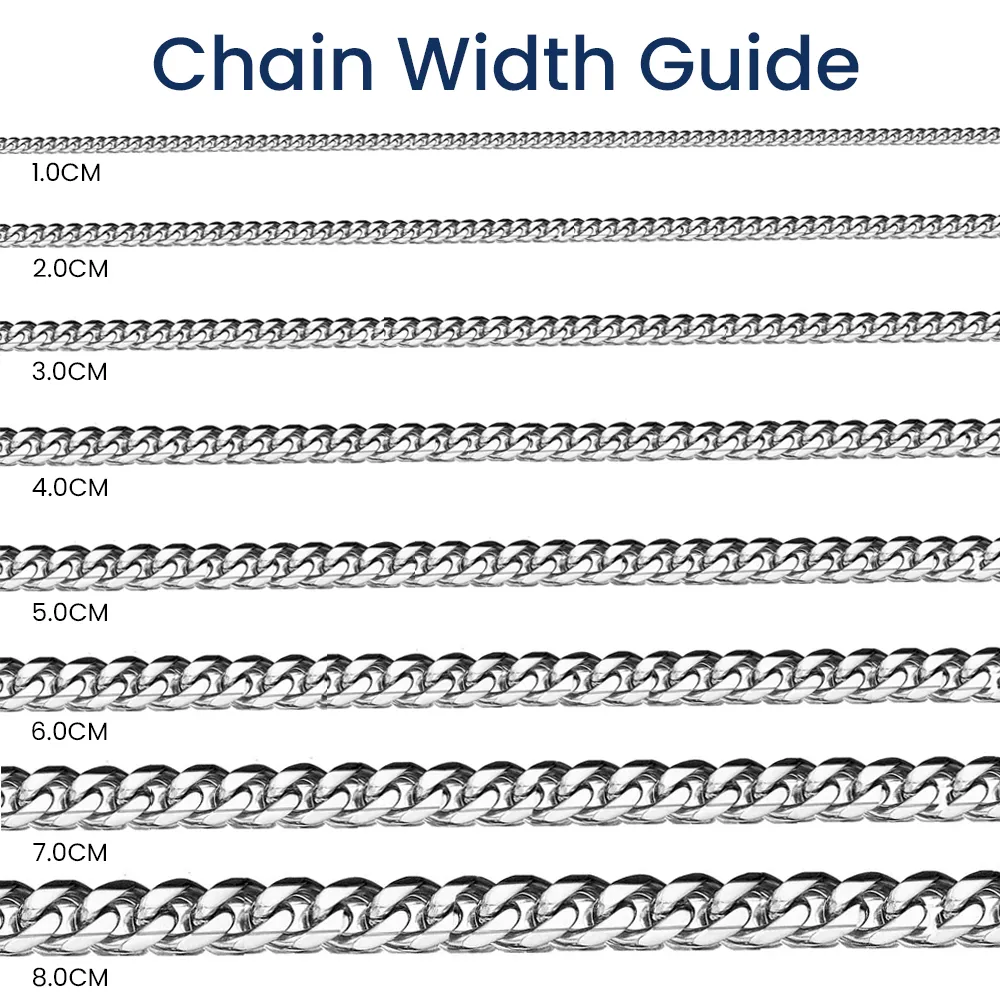

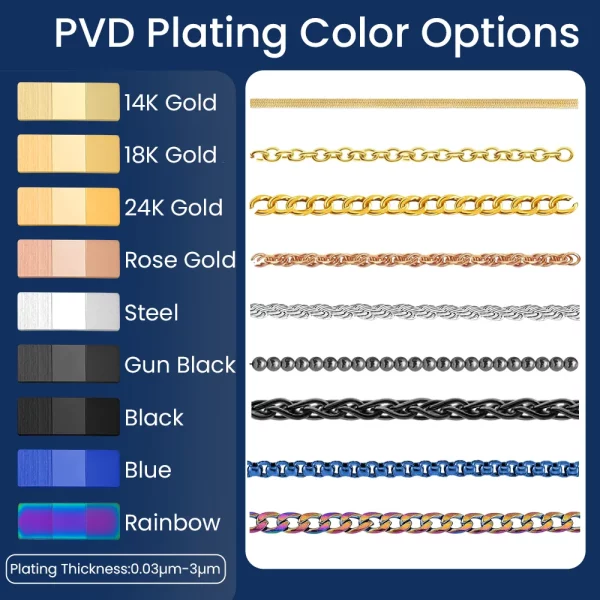

Custom Chain Size

Custom Stainless Steel Chain Style and Color

Material: Stainless Steel

Custom Components

Custom Necklace Packaging

Custom Jewelry Process

Concept & Requirement Lock-in

Client Briefing: The client provides the initial design, material specs (e.g., Stainless steel, 14K Gold), stone requirements, and required order volume (MOQ). Supplier Vetting: We assess feasibility, finalize the budget, and confirm the production timeline.

Design & Engineering Modeling

3D CAD Modeling: We create high-resolution 3D computer-aided jewelry design models and realistic renderings. Client Sign-off: We send the 3D files for your final approval. Three revisions are addressed until the design is perfect.

Prototyping & Sample Approval

We will create the first metal sample in short time. Client Review: You receive the sample to check dimensions, fit, quality, and weight.

Mass Production & Finishing

Tooling: Durable molds are prepared for high-volume casting. Assembly & Setting: Casting, assembly, welding (laser welding for durability), and stone setting. Finishing: Detailed polishing, plating, and special treatments.

Quality Control & Delivery

Client Briefing: The client provides the initial design, material specs (e.g., Stainless steel, 14K Gold), stone requirements, and required order volume (MOQ). Supplier Vetting: We assess feasibility, finalize the budget, and confirm the production timeline.

After-Sales Support & Reordering

Warranty: We provide a standard quality warranty against manufacturing defects (e.g., plating defects, structural issues). Reordering: We keep your design files and molds securely archived for easy and immediate reorders.

FAQ

Q1: What is the standard lead time and cost for prototyping?

A1: Our standard sampling process typically takes 7 to 10 business days. Prototyping costs vary based on design complexity and material requirements; however, these fees are generally fully refundable upon the placement of a bulk production order that meets our minimum order quantity (MOQ).

Q2: How do you guarantee consistency between the approved sample and mass production?

A2: We utilize a “Golden Sample” protocol. Once the prototype is approved, it serves as the definitive technical benchmark for the production line. Our Quality Control (QC) team conducts multi-stage inspections to ensure that every piece in the bulk order maintains the exact specifications, tolerances, and finish of the original sample.

Q3: What is the total turnaround time from order confirmation to final delivery?

A3: For most mass production orders, the lead time is approximately 25 to 45 business days following final design approval and deposit receipt. This timeframe may fluctuate slightly depending on the volume and technical intricacy of the collection.

Q4: Are public holidays factored into the production schedule?

A4: Our quoted lead times refer to actual working days. We recommend that clients account for major statutory holidays when planning seasonal launches. Our account managers will provide an adjusted production timeline well in advance of any scheduled facility closures.

Q5: Do you offer design assistance, or must we provide technical drawings?

A5: We offer comprehensive OEM and ODM services. Whether you provide finished 3D CAD files or initial conceptual sketches, our in-house engineering team can assist with technical rendering and structural optimization to ensure your designs are production-ready.

Q1: What are the durability standards for your plating and finishes?

A1: We utilize Real Gold Plating (available in 14K, 18K, or 24K) to ensure a premium, long-lasting finish. Depending on your brand’s requirements, we offer plating thicknesses ranging from 0.3 μm to 3.0 μm . This high-specification process is engineered for superior wear resistance and color retention, preventing tarnishing and ensuring the jewelry maintains its luster under daily wear.

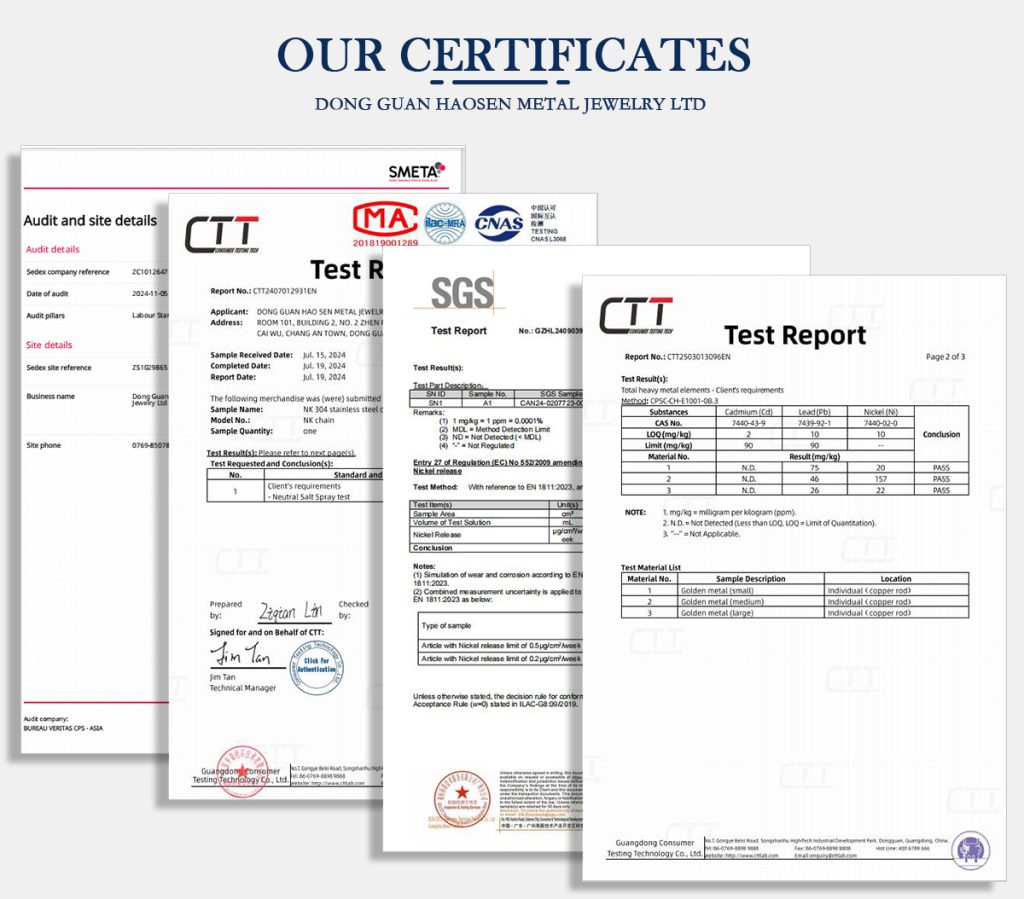

Q2: What quality certifications and laboratory test reports can you provide?

A2: We are committed to full compliance. Upon request, we can provide Material Analysis Reports and third-party certifications (such as SGS or Intertek) verifying that our products are lead-free, nickel-free, and compliant with REACH and RoHS standards.

Q1: What is the standard payment structure?

A1: Our standard commercial terms require a 30% deposit to initiate production, with the remaining 70% balance payable upon completion and prior to dispatch.

Q2: What payment methods and trade terms do you accept? A2: We accept payments via Wire Transfer (T/T), Credit Card, and Letter of Credit (L/C) for high-volume contracts. Most shipments are processed under EXW or FOB terms, depending on your preference.

Q3: Which logistics providers and shipping methods are available?

A3: We partner with major global couriers including FedEx, DHL, and UPS for door-to-door express delivery. For larger shipments, we can coordinate with freight forwarders for air or ocean cargo to optimize your landing costs.

Q4: Do you accommodate on-site factory audits? A4: Transparency is a core value of our operation. We welcome third-party factory audits and client inspections. Please coordinate with your account manager to schedule a visit to our facility.

Q5: What is the return policy for bespoke/customized jewelry?

A5: Due to the proprietary nature of custom-made jewelry, we do not accept returns .

Trusted B2B Partners Worldwide

Our Certifications & Compliance

Raw Material & Nickel Release Certification

Nickel Release & Lead-Free Compliance: We prioritize your customers’ safety by ensuring all raw materials are up to code. Our products undergo rigorous testing to meet REACH and RoHS standards, specifically focusing on nickel release to prevent skin irritation. We provide full laboratory reports ensuring our jewelry is hypoallergenic and safe for long-term wear, giving you peace of mind that your brand is protected.

Salt Spray Test Report

Salt Spray Corrosion Testing: To ensure our jewelry doesn’t lose its luster in harsh conditions, we conduct standardized Salt Spray Tests (up to 48-96 hours). This process simulates long-term exposure to sweat and humidity, proving our products’ superior anti-tarnish and anti-corrosion capabilities. Our pieces are built to stand the test of time, even in coastal or high-humidity markets.

Plating Thickness Measurement

we provide Genuine Gold Plating that sets the gold standard for durability. Our factory utilizes X-ray fluorescence (XRF) testing to verify plating thickness, ranging from 0.3 microns to 3.0 microns (Vermeil grade). This ensures every batch meets your exact specifications for premium quality and wear resistance.

Sedex / SMETA Audit Report

We believe in doing business the right way. Our factory is Sedex-certified, having passed the SMETA audit which covers ethical trade, health and safety, and environmental standards. This “extended” audit report demonstrates our commitment to a transparent supply chain, ensuring we are a partner you can vouch for when it comes to social and ethical accountability.

Contact With Us

We specialize in handling tall orders with the precision your jewelry brand deserves. From initial concept to mass production, let us do the heavy lifting so you can focus on what you do best—selling.