Case Study: A Partnership in Fashion Accessories

Abstract: This article provides a detailed account of our successful collaboration with the renowned brand, starting from our initial meeting at the Canton Fair in Autumn 2024 to securing the bulk order for their Autumn 2025 collection. It highlights how our professional product solutions, technical adaptability, transparent communication, and unwavering commitment to quality built the trust needed to win this key client, serving as a practical reference for businesses aiming to partner with premium brands.

The Initial Connection: Opening Doors with Product Strength

At the Autumn 2024 Canton Fair, our innovative product designs and sophisticated craftsmanship captured the attention of the Client. Their team engaged in in-depth discussions with us on-site, exploring product features and potential collaboration, planting the initial seed of trust.

Shortly after the fair, we received their proactive inquiry. Following our established client onboarding process, we promptly dispatched product samples aligning with their brand aesthetic. After rigorous quality inspection, the client highly commended our product quality. This critical step led them to share their development plan for the Autumn 2025 collection, inviting us to propose customized solutions.

Seizing this opportunity, our team responded swiftly. After conducting precise cost calculation and quotation, we engaged in multiple efficient communication rounds with the client, finalizing technical specifications, delivery timelines, and cooperation terms.

Tailored Solutions: Translating Brand Vision with Technical Expertise

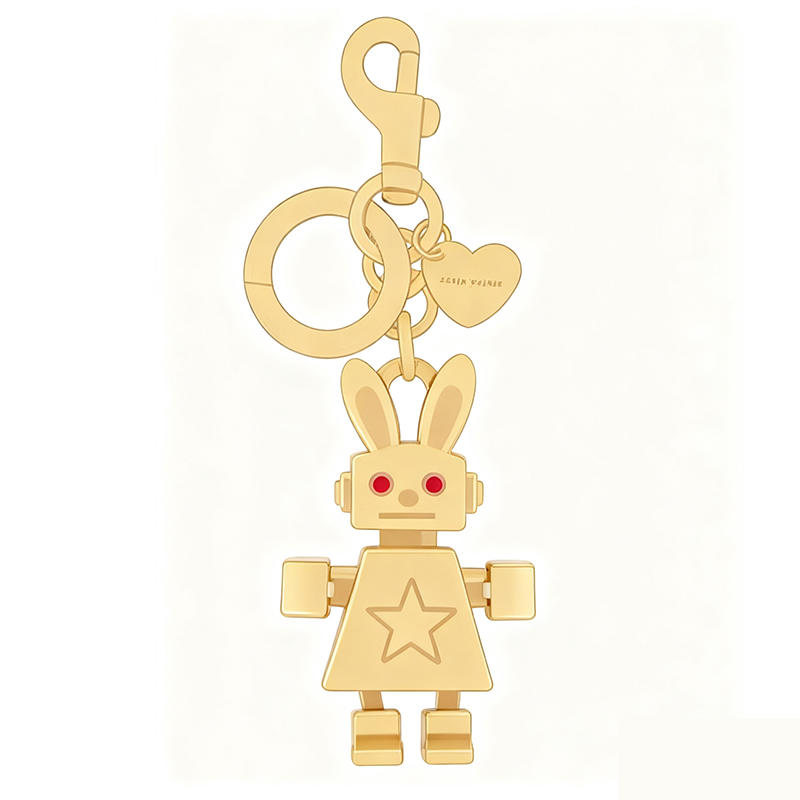

The customization focused on two products: a branded keychain and a distinctive Cuban chain necklace.

Keychain Solution: Efficient Response & Precision Tooling

The client required a keychain comprising standard parts and a custom rocket pendant with their logo printed on the back. Our technical team confirmed the feasibility and proceeded with 3D modeling based on the client’s precise dimensions, followed by tooling initiation.

Necklace Solution: Innovative Design Solving Core Challenges

While the necklace body was a standard Cuban chain, the client requested a custom clasp: a circular design embedded with their logo. Addressing the limitations of conventional clasps, our R&D team proposed an innovative “Top-Bottom Magnetic Closure” solution. This design ensured ease of use while enhancing the product’s perceived value through its unique mechanism. We provided detailed documentation, along with reference images and a demonstration video for clarity, leading to the client’s approval.

Sample Development: Building Trust Through Transparency

As a first-time partner, the client requested a virtual factory audit. We cooperated fully, showcasing our production facilities, quality control systems, and capacity, which significantly strengthened their confidence. Upon audit completion, the client paid the sample fee, and production commenced.

Necklace Sample Refinement: During the clasp design phase, our designers identified that the original size would compromise logo legibility. We proactively communicated this issue along with an optimization proposal (slightly increasing the clasp and logo size). After discussion, the client appreciated our professional input and approved the adjustment.

Keychain Sample Progress: We efficiently utilized existing inventory for standard parts (clasp, jump ring), avoiding additional tooling costs and time. The core rocket pendant proceeded smoothly with tooling based on the approved 3D model.

Upon receiving and inspecting the samples, the client highly praised our exceptional product quality, proactive optimization suggestions, and efficient project execution. Based on this solid foundation of trust, they proceeded directly to place bulk orders for both items.

Quality Enhancement: Exceeding Expectations with Foresight

A pivotal moment occurred during our follow-up meeting at the Spring 2025 Canton Fair. The client presented their previous similar products, and our technical expert identified that our initially planned alloy material wouldn’t match the superior finish of their existing items.

Instead of proceeding as planned, we proactively proposed upgrading the material to brass. This sincere recommendation, rooted in a commitment to quality, was immediately appreciated and approved by the client. We promptly implemented the material change at our factory.

After approximately 20 days of meticulous production, both samples were ready. Before shipping the physical samples, we sent high-resolution images (highlighting the branded clasp and assembled keychain) for final confirmation.

Successful Outcome & Future Collaboration

Currently, bulk production is underway according to schedule, with strict quality and timeline controls in place to ensure flawless delivery. This successful partnership with the client is not merely a transaction but a robust testament to our capability as a strategic supply chain partner for premium brands. We look forward to building a long-term, synergistic relationship with Client.

If you are seeking a reliable, professional, and growth-oriented supply chain partner for your brand, please get in touch. Let’s explore how we can achieve great things together.